Filter Plates: Products & Technology

Klinkau offers a wide range of possibilities for your filtration needs. We have the right solution for your filtration challenge starting from filter plate and frame systems, via chamber and membrane filter plates to specialised solutions for ATEX or medical applications.

We are happy to help! Contact us via our contact form or by phone +49 8342 40050!

Plates and Frames

The oldest and longest known method for separating solids from liquids. Cake thicknesses from 10 to 60 mm are possible.

Chamber Filter Plates

Development of the plate and frame filter plate with an integrated plate frame. This enables filtration pressures of up to 50 bar.

Membrane Filter Plates

Membrane filter plates also use membrane squeezing during the phase of pressure filtration whereby filtration times are reduced.

Special Components

Special components are manufactured individually according to customer requirements.

Envirotech Products

EnviroTech Molded Products offer heavy-walled, large-volumed specialized components.

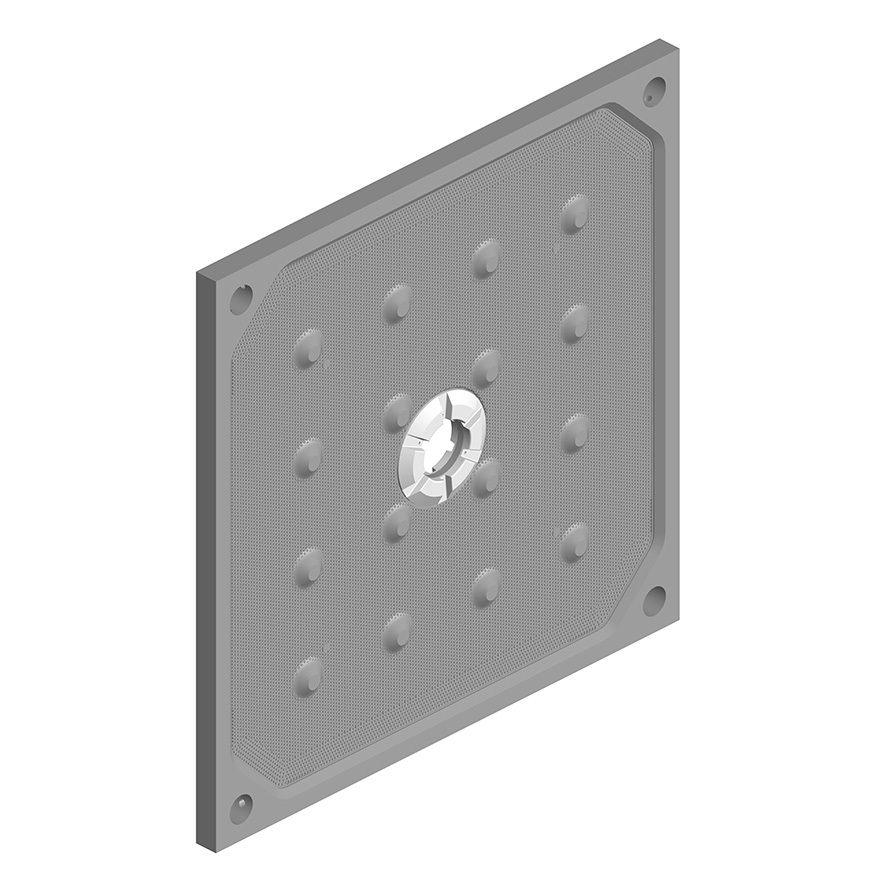

Function & Construction

In pressure filtration two filter plates create a sealed cavity called the filtration chamber. Inside the filtration chamber the solids are captured and form a filter cake. At the same time it has to secure the filter medium (cloth, needle felt, paper) to the plate and seal it tight in the appropriate places to the outside.

In general, a filter plate consists of a sealing edge and the plate web. This is independent of the type of filter plate e.g. chamber filter plate or membrane filter plate. On the surface of the plate web small pips are present to form an area where the filtrate can discharge once it passed through the filter cloth. The solids are captured on the filter cloth and forms the filter cake whereas the filtrate passes through it, is collected between the pips and then flows to the filtrate discharge holes. From there it is discharged via the filtrate discharge holes and filtrate discharge channels to the corner ports. These corner ports form a collection channel across all filter plates that collects the filtrate and guides it out of the filter press. Stay bosses on the plate web provide mechanical stability and prevent bending of the filter plate under occurring differential pressure.

Membrane filter plate specific are two inflatable membranes that are attached to the body plate. These membranes can be used to dewater the filter cake through mechanical squeezing.

Two types of filter presses are distinguished: overhead beam and side bar filter presses.

In an overhead beam filter press the filter plates are mounted suspended via a steel bar from the top of the press, whereas they are resting on so called handles attached to the filter plates in a side bar filter press.